Technology

The existing construction standards and market requirements have challenged us to modernise our planning and design of houses. High energy efficiency requirements, thermal bridges, lack of hermeticity are barriers for many traditional types of construction.

SIP technologies belong to the new carcass construction generation. Unprecedented speed of construction, universal usage, high tenacity standards and insulation qualities prove that SIP technology is a high efficiency construction system suitable for building passive and zero energy waste houses.

Construction with SIP panels belongs to the carcass construction, however, its physical and insulation qualities substantially exceed those of traditional carcass houses.

The basis of construction is the SIP panel. The panel consists of two 12 mm OSB sheets between which a single length EPS plate (foam polystyrene) or EOPOR (foam polystyrene with graphite filling) is glued under pressure. The production process results in a sandwich panel with excellent insulation, low volume density and high structural hardness. SIP is an ecological and environmentally friendly technology.

We produce panels of various thicknesses that can be used for external walls, internal bearing walls, room separating walls, floors, interflooring, foundations and roofs.

|

Name |

Thickness, mm |

Filling substance |

U value (W/ m2K) |

Purpose |

|

SIP122E |

122 |

EPS 80 |

|

Room separating walls, outbuildings |

|

SIP172E |

172 |

EPS 80 |

0.25 |

Outer walls and bearing walls |

|

SIP172N |

172 |

Neopor 80 |

0.20 |

Outer walls and bearing walls |

|

SIP222E |

222 |

EPS 80 |

0.19 |

Outer walls, interflooring and roofs |

|

SIP222N |

222 |

Neopor 80 |

0.15 |

Outer walls, interflooring and roofs |

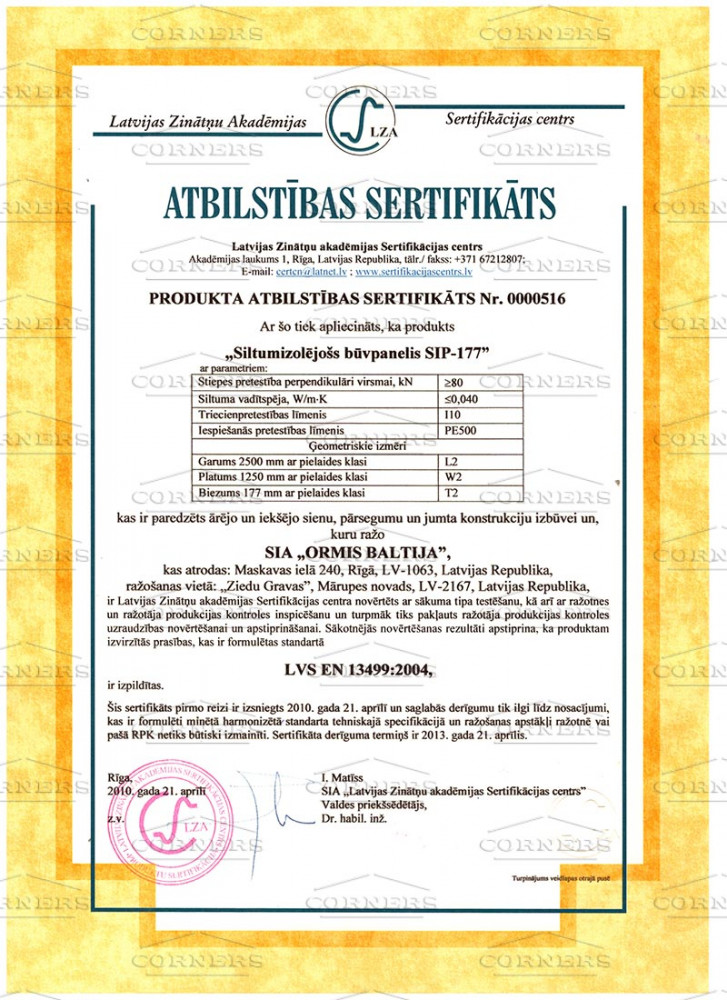

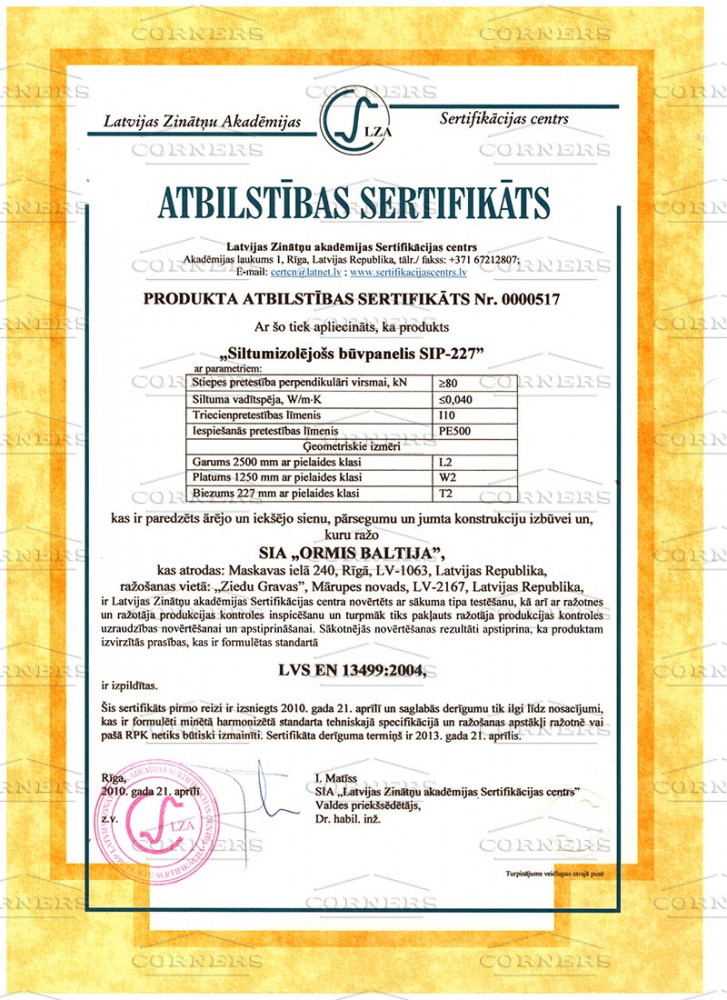

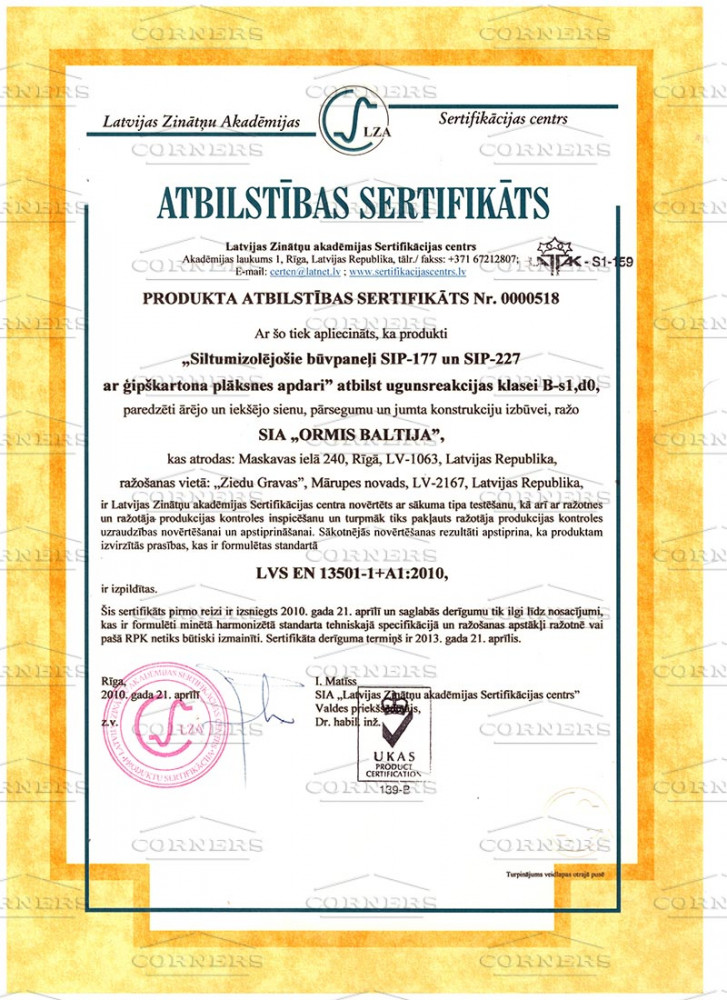

Our panels have European certification; the production process is certified and it is regularly controlled by the supervisory institutions.